RUGS - 1953 INSTRUCTIONS

This is a section from a 1953 book about rugmaking techniques. You'll see that the canvas is the patons 8-holes style with tramlines on both warp and weft, rather than twisted weft.

RUGMAKING

By Rosemary Brinley (1953)

Needlework and Knitting Editor of Craftworker Magazine.

The hooked method of making rugs. Tools used - speed of the work - materials and tools required - latch hook and gauge - use of other materials - backing material - dimensions and design - designing a pattern - preparing the wool - use of the gauge - starting the rug - knotting the tufts - direction of the pile - backing the rug - treatment of edges - alternative foundation material.

One of the most popular forms of rugmaking is the hooked rug method of making piled rugs on a foundation of open-mesh canvas. In this method, a tool known as a “latch hook” is used to hook, pull and knot short lengths of rug wool to the canvas background. The work cannot be done very quickly, although it will be found, after practise, that a rhythmic speed may be attained. Because of the time taken and the cost of the materials used, the hooked method may not be found a very profitable way of making rugs for sale. However, not all home workers practise their craft for profit and it will be found that the hooked method of making rugs produce some very fine examples of work and the rugs made are warm, comfortable and have a very long life which, to some extent, offsets the high cost of their production.

The main things required for this branch of the craft are, some open-mesh canvas, which is supplied in lengths varying in width from twelve inches to forty-eight inches, some rug wool, which is supplied in skeins or in packets cut ready for use, a latch hook and a gauge to assist in cutting the wool to the correct length for the tufts. In addition to the materials and equipment already described for use in this particular branch of the craft, the rug- maker will require some tools used generally in all forms of rugmaking. These are a pair of sharp scissors and some carpet needles in various sizes and, in some branches of the craft, a razor blade will be found very useful.

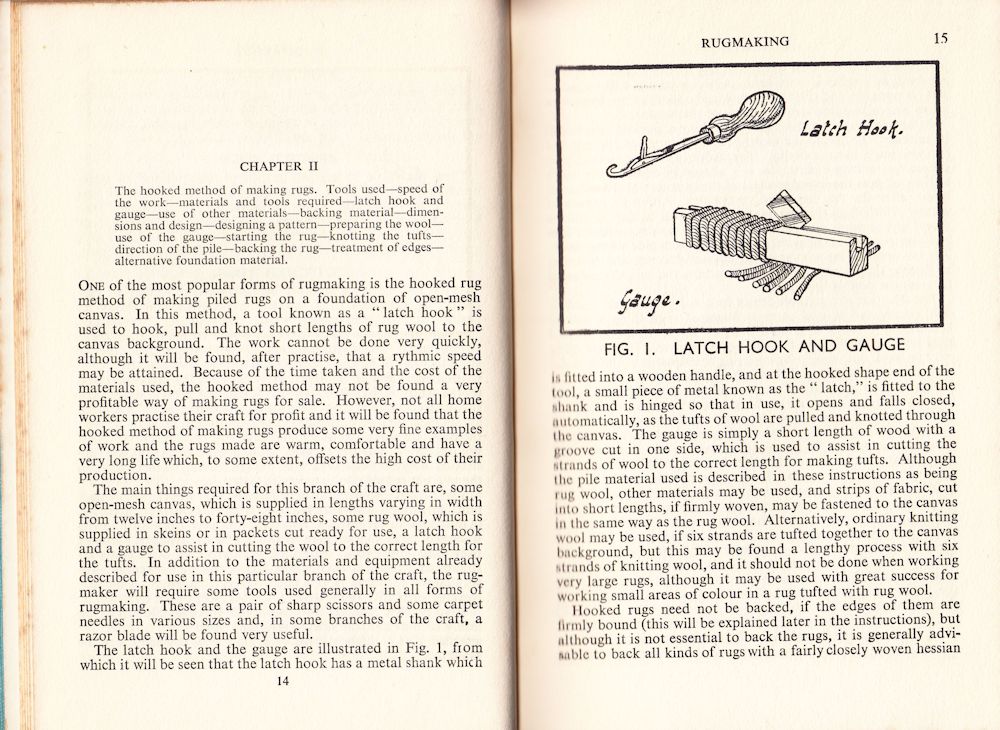

The latch hook and the gauge are illustrated in Fig. 1, from which it will be seen that the latch hook has a metal shank which is fitted into a wooden handle, and at the hooked shape end of the tool, a small piece of metal known as the “latch,” is fitted to the shank and is hinged so that in use, it opens and falls closed, automatically, as the tufts of wool are pulled and knotted through the canvas. The gauge is simply a short length of wood with a groove cut in one side, which is used to assist in cutting the strands of wool to the correct length for making tufts. Although the pile material used is described in these instructions as being rug wool, other materials may be used, and strips of fabric, cut into short lengths, if firmly woven, may be fastened to the canvas in the same way as the rug wool. Alternatively, ordinary knitting wool may be used, if six strands are tufted together to the canvas background, but this may be found a lengthy process with six strands of knitting wool, and it should not be done when working very large rugs, although it may be used with great success for working small areas of colour in a rug tufted with rug wool.

Hooked rugs need not be backed, if the edges of them are firmly bound (this will be explained later in the instructions), but although it is not essential to back the rugs, it is generally advisable to back all kinds of rugs with a fairly closely woven hessian which should be stitched under the rug, at the edges. A special rug-backing hessian is obtainable, which is coated with an adhesive on one side, and this type is fastened under the rug by using a Warm smoothing iron over the back of the hessian.

Before commencing the work of making a hooked rug, it will be necessary to decide the dimensions and shape of the rug and to work out a pattern design. The width of the rug canvas, purchased for making a particular rug, should be equal to the width of the rug, plus the selvedge edges of the canvas, which are turned under after the rug has been completed. Although canvas of greater width than the rug may be cut down to size, it will be found best to work on the correct width of canvas, so that a firm selvedge edge of equal width runs along each side of the work. The cut ends of the canvas at the ends of the rug are neatened by folding them under the rug and working the end rows of wool through the double thickness.

The selection of a suitable design for a rug, is a matter of individual consideration, and in most forms of rugmaking it will be found best to work to a bold design. The designs for hooked rugs may be marked on the open-mesh canvas. They are quite easy to work out, simply by counting the squares in the foundation across the width and down the length, upon which basis a design may be planned. The coloured areas can be marked out on the canvas with crayons or chalk, or a design may be drawn on squared graph-paper, with each square on the paper representing one square of the rug canvas. (Most rug canvases have large squares over-printed on the smaller squares, in colour, to assist in counting the squares and dividing the background when designing a pattern.) If the rugs are being made for sale, it will be found best to use the graph-paper method of designing a pattern, and after a rug has been completed, the patterned paper may be stored for future use, and in this way a library of patterns may be built up. Designs should always be well balanced, and the beginner will be well advised to commence with simple designs. After the canvas has been trimmed to size at the ends (three or four rows extra should be allowed at each end for turning under), and after the pattern design has been planned and made, the rug wool should be prepared for use.

This is done by cutting it into short pieces of equal lengths. First wind a skein of wool into a ball and from the ball wind a strand of wool over the wooden gauge, and round and round it as illustrated in Fig. 1. The wool should be firmly bound round the gauge, but it should not be stretched. Care should be taken in this part of the work, to keep the tension even. This is to ensure that the short pieces for the tufts are cut to even lengths, and after the wool has been wound round the gauge, a razor blade or pair of sharp scissors should be used to cut through the windings along the grooved side of the gauge, as shown in the illustration, Fig. 1. Before commencing the work of fastening the tufts of wool to the foundation canvas, a good quantity of lengths should be cut.

After working one or two rows of the rug, the rest of the work should be carried out on a table, with the unworked canvas resting on the table and held in place with a weighty object. The rows of tufts should be worked across the width of the rug, and to commence, two or three rows of the squared canvas should be turned under, and an allowance should be made for this when tuning the canvas to size. The first rows of the rug, across the background, should be done by working tufts through the double thickness of canvas.

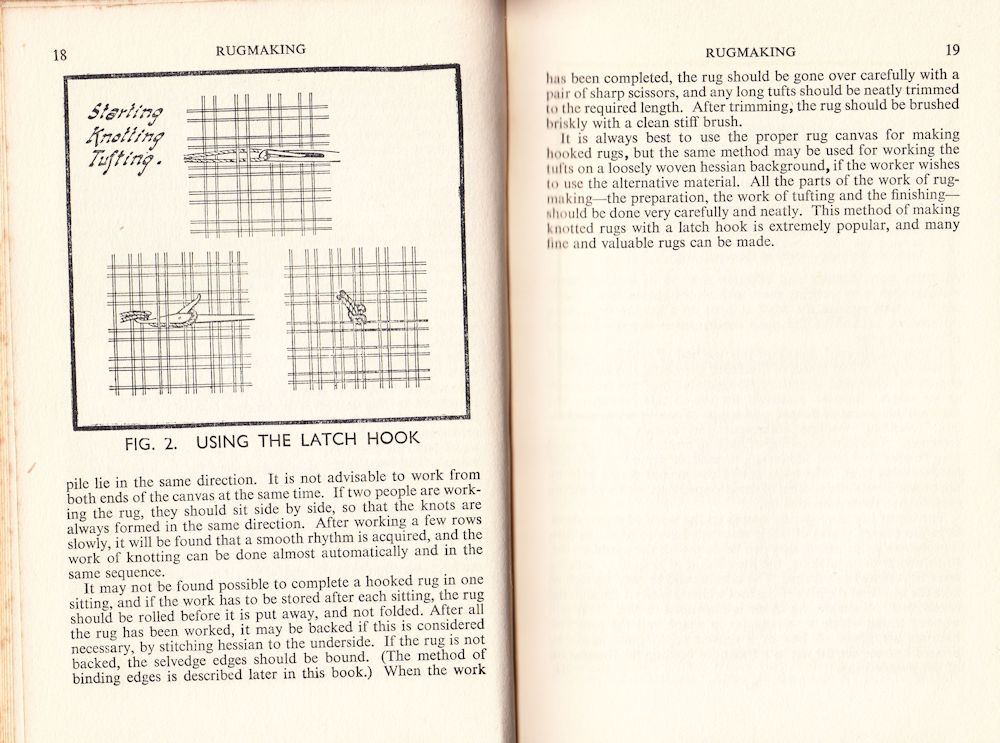

In working the rows of tufts, the latch hook is used to knot each tuft of wool to the strands forming one side of a square of the canvas mesh. The method of knotting and tufting wool is illustrated in Fig. 2, and it is done as follows: first, push the latch hook through one of the squares in the canvas, under a cross thread, up through the next square in front and allow the small latch to fall back and open, then take one of the short pieces of rug wool, fold it double and place the doubled end in the hook, holding the two ends together. Pull the latch hook through the canvas towards you and as this is done, the latch will close. While the tool is being drawn through the canvas, the ends of the wool should be held firm, then the tool should be moved forward through the small loop at the double end, and hooked round the two strands of wool. The tool should then be pulled back through the loop, closing the latch, and pulling the two ends of the wool through the loop to form a knot. To finish the knot, the ends of the wool should be tugged to attach each tuft firmly to the canvas.

It is important during the work of knotting tufts to the canvas, to work in the same sequence all the way through. The knots should always be formed in the same direction, and when the hook is turned, it should always be turned in the same way. This not only assists in speeding up the process, but it helps to make the pile lie in the same direction. It is not advisable to work from both ends of the canvas at the same time. If two people are working the rug, they should sit side by side, so that the knots are always formed in the same direction. After working a few rows slowly, it will be found that a smooth rhythm is acquired, and the work of knotting can be done almost automatically and in the same sequence.

It may not be found possible to complete a hooked rug in one sitting, and if the work has to be stored after each sitting, the rug should be rolled before it is put away, and not folded. After all the rug has been worked, it may be backed if this is considered necessary, by stitching hessian to the underside. If the rug is not backed, the selvedge edges should be bound. (The method of binding edges is described later in this book.) When the work has been completed, the rug should be gone over carefully with a pair of sharp scissors, and any long tufts should be neatly trimmed to the required length. After trimming, the rug should be brushed briskly with a clean stiff brush.

It is always best to use the proper rug canvas for making hooked rugs, but the same method may be used for working the tufts on a loosely woven hessian background, if the worker wishes in use the alternative material. All the parts of the work of rug-making - the preparation, the work of tufting and the finishing - should be done very carefully and neatly. This method of making knotted rugs with a latch hook is extremely popular, and many fine and valuable rugs can be made.

You are visitor number: