RUG SUPPLIES - MERRYWEAVE and FURNI-KIT

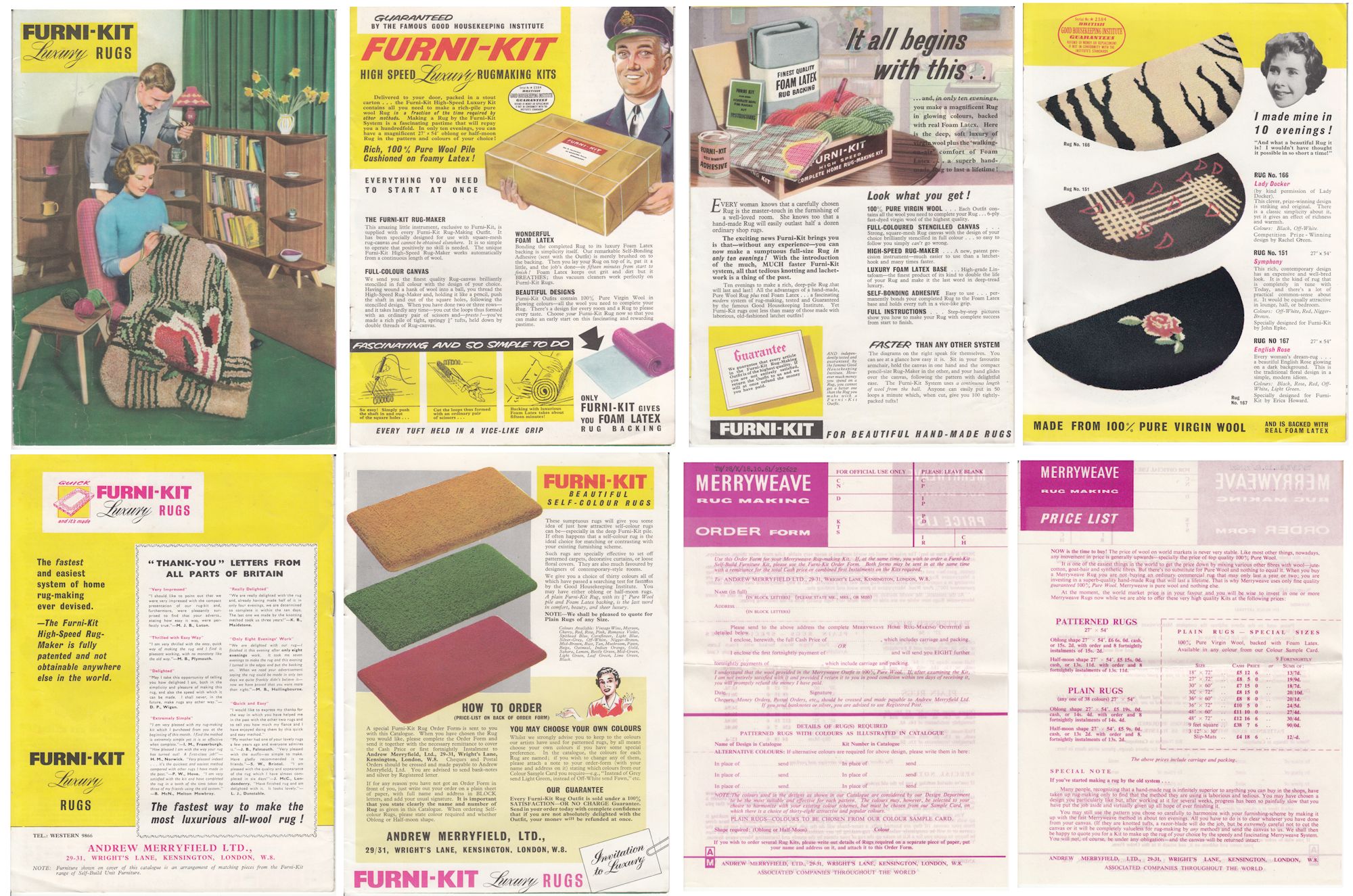

The Furni-Kit Luxury Rugs brochure appears to be the predecessor to the Merryweave brand. Based on the 1955 patent filing date for the rug-making tool, this was probably from 1955/6, before the rugs were branded as Merryweave.

The Merryweave system (as a brand) was marketed in 1957 by Andrew Merryfield Ltd who had a showroom in Kensington, London. The only information I could find comes from their catalogue. Merryweave was not just a range of stencilled canvases, it was a rugmaking system. Each outfit was supplied with the right amount of 6-ply, 100% Pure Virgin Wool – if you tried to latch hook the rug, you wouldn’t have enough wool to complete. The rug canvas was stencilled in full colour with the chosen design. Although not recommended, the customer could choose his or her own colours for any of the patterned rugs by stating “instead of light green send light blue” etc. The kit contained the Merryweave Hi-Speed Rug-Maker, a supply of self-bonding agent (i.e. adhesive), foam latex backing cut to the right size and an illustrated step-by-step instruction booklet. It was boasted that a full-size Merryweave rug could be made in only ten evenings. “Merryweave rugs are moderately priced and cost no more—in some instances, less—than the old- fashioned, backless latchet-hook outfits.”

The Merryweave brochure promised customers that one of the most rewarding and satisfying of pastimes had been brought right up to date with their “new, easier, really enjoyable way to make the loveliest, most luxuriously comfortable rugs you’ve ever seen.” In addition to the deep-pile pure virgin wool, there was the “walking-on-air” luxury of a foam latex backing. In fact the backing was necessary to keep the tufts or loops in place. The tufts were rooted in the canvas mesh, and “life-bonded” to a breathable foam-latex backing that kept out grit and dirt. For the aspirational householder, these had an air of quality and looked expensive.

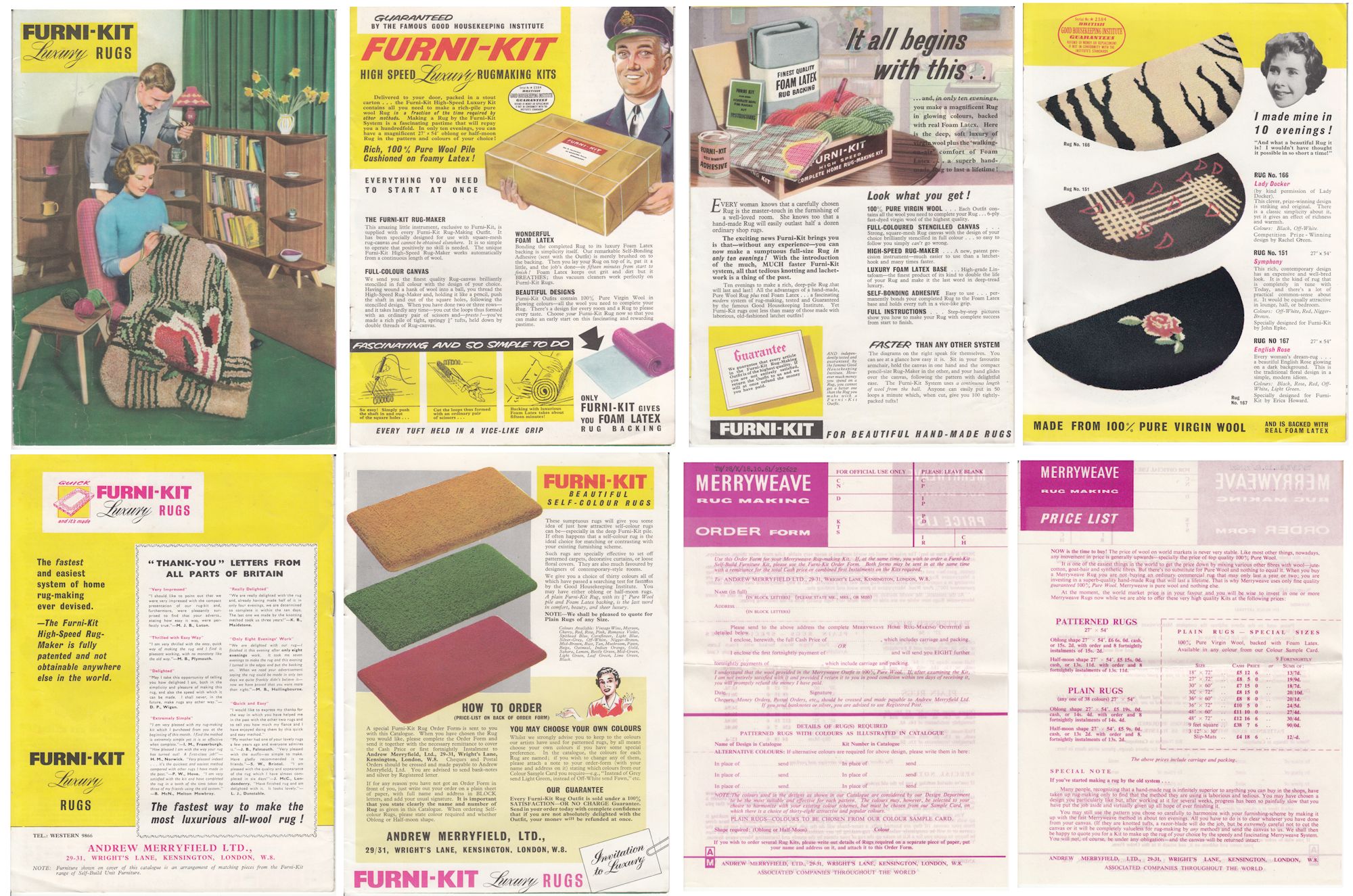

The unique high-speed rug-making tool was “small, compact, sturdy, no bigger than a pencil” and, being patented, was unobtainable anywhere else. The Merryweave Rug- Maker claimed to out-date old-fashioned knotting methods, but was really just a variation on the traditional punch-needle. The ball point tip made it glide over the canvas, rapidly “planting” the deep Merryweave pile from a continuous length of wool. It was basically a rug-punch tool for use on latch-hook canvas.

“In one hand, lightly hold the stencilled rug-canvas— in the other, a small fascinating instrument. Move it in and out of the mesh. Watch it glide over the canvas, effortlessly following the pattern. See, as if by magic, the tightly- packed loops ‘growing* one after another, while a continuous length of wool from the ball automatically feeds into the rug-making tool. When you’ve done a few rows—and, if you want to, you can put in as many as 50 loops a minute—snip the loops with an ordinary pair of scissors and—presto!—the loops have sprung apart into a deep, thick rug pile!

But this is not all. When the rug is completed, you cushion it with luxury foam latex—a simple job that takes only 15 minutes. Simply brush the bonding-agent (supplied with each outfit) onto the backing, lay your rug on top of it—pat it a little with your hand . . . the rug bonds itself to the foam latex and every single tuft is securely anchored. Once the bonding-agent has done its work, the tufts are there for the life of the rug—and what a fabulously long life your Merryweave rug will have! Yes—you can wash it as many times as you like . . . even shamelessly ill-treat it. . . the tufts will stay put and the rug will stay beautiful and defy you to wear it out.”

According to the advertising, Merryweave rugs were given the most rigorous life-tests: the wools were subjected to powerful ultra-violet rays to ensure they didn’t fade; the pile, was friction-rubbed by a special machine to mimic many years of normal use; the foam latex backing was “mercilessly” baked in high-temperature ovens. Being simple to make and having survived all of this testing, Merryweave rugs were awarded the Seal and Guarantee of the Good Housekeeping Institute. Merryweave rug wools were (according to the brochure) fast-dyed and thoroughly tested in their Bradford factory. The few shades that were difficult to “fix” against fading (in sunlight or the wash) were rejected from their range to ensure that the rugs .

Finally, Merryweave fired this shot at the other rug-making suppliers: ‘There is an important difference between “Virgin Wool” and what may legitimately be called “Pure Wool.” All too often, “Pure Wool” is reconstituted wool—i.e., wool that has been obtained from disused woollen goods and subjected to an elaborate process of bleaching, etc., to reclaim it. Pure Virgin Wool retains its natural oils, elasticity and long-lasting qualities. We unreservedly guarantee that no reconstituted wool is ever used in Merryweave Rugs. Every single tuft on your Merryweave Rug will be 100% Pure Virgin Wool.’

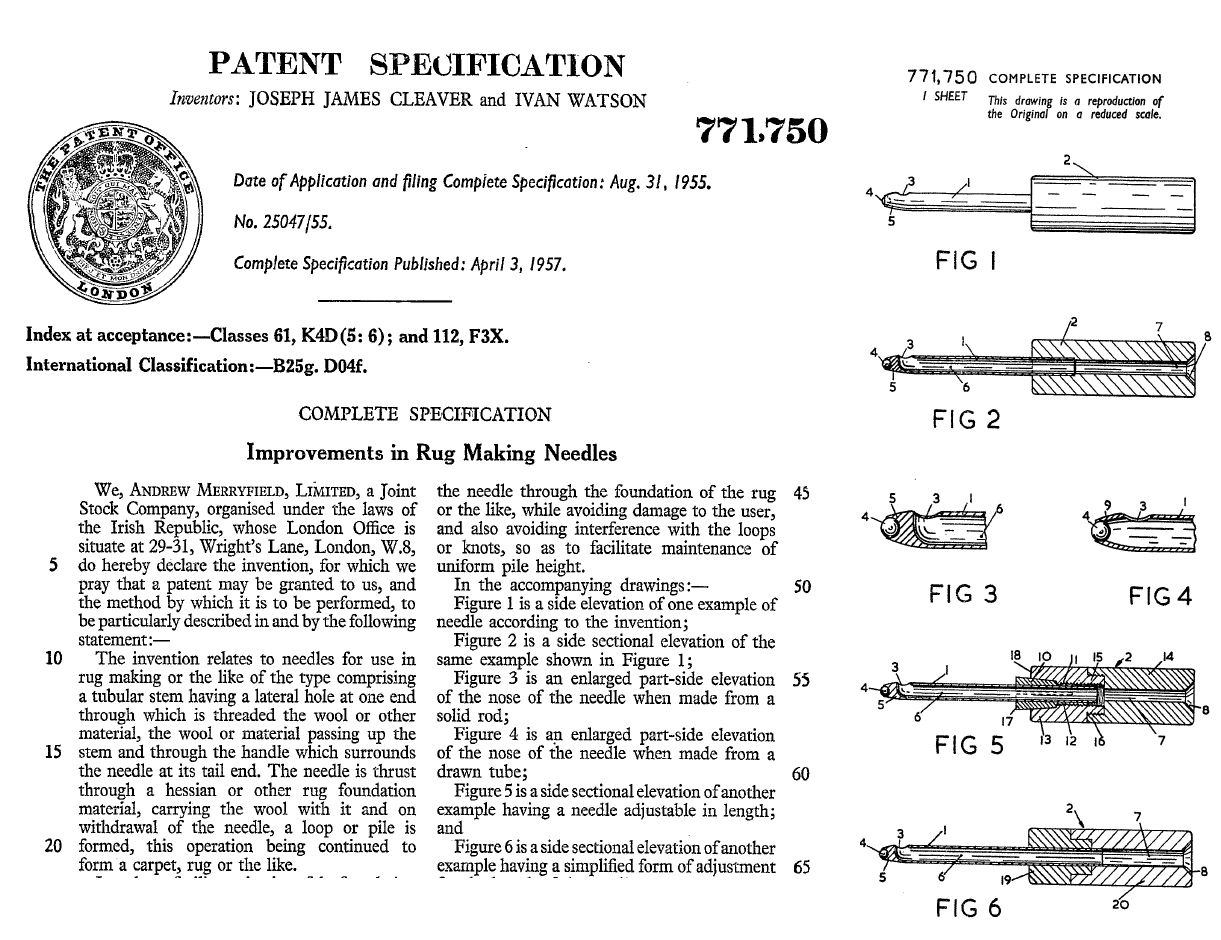

“Merryweave” was just one of the home innovations marketed by Merryfield, but unlike the “Gram-deck” and “Furni-Kit” it seems to have vanished into obscurity. In 1959, the company marketed the "Gramdeck", an affordable reel-to-reel tape recorder attachment for use with a record player; this fitted onto the turntable and used the turntable to drive the tape deck. They also marketed “Furni-kit” which was affordable luxury (in the 1950s) flat-pack furniture ordered from a catalogue or the Kensington showroom for home assembly. The illustrated catalogue was titled "I Made It Myself" and included needlework cabinets, bookcases, tables, bureaus, occasional tables, record cabinets, bathroom stools, tea trolleys, lamp standards, dressing tables, and other self-assembly furniture.

|

You are visitor number: