RUG-MAKING HISTORY - THE BLACKHAM “SPEEDEWAY” RUG OUTFIT

This isn’t latch-hooking, but the "Blackham Speedeway Rug Outfit" came in a box of assorted rug-making equipment along with some latch-hooking supplies. I discovered that it wasn't documented online, but luckily it had a British patent number (470642) stamped on the wooden part so I did a bit of digging to find out more and, as all good historians tend to do, I decided to document it here for other people! If you want to know more, the patent (GB470642) is easy to find online.

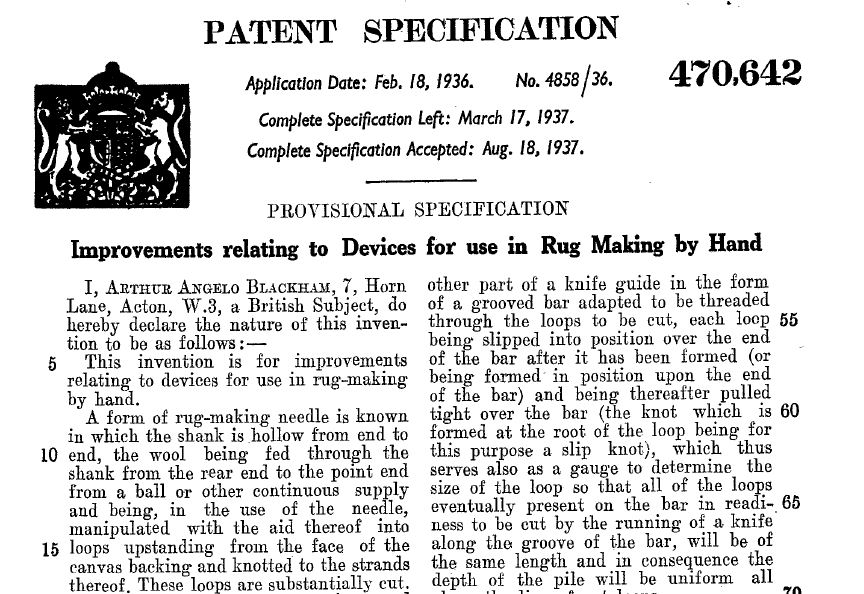

Title: Improvements relating to devices for use in rug making by hand

Patent Application Number: GB19360004858 19360218

Patent Publication Number: 470642 (A)

Application Date: February 18, 1936

Publication Date: August 18, 1937

Assignee (inventor): Arthur Angelo Blackham

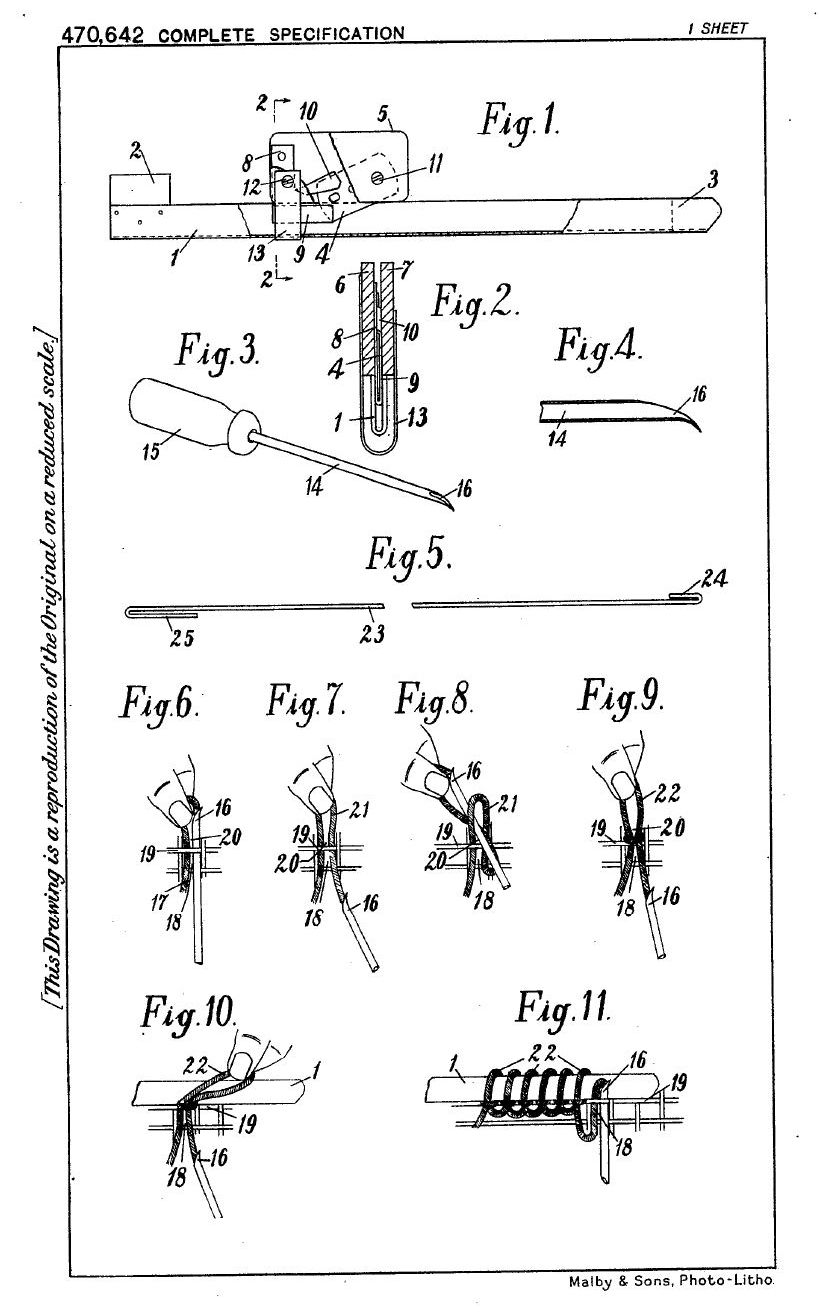

Patent GB470642 is described as “470,642. Hand tufting-tools. BLACKHAM, A. A. Feb. 18, 1936, No. 4858. [Class 112] [Also in Groups VIII and IX] Tufted fabrics are made by pushing a needle 14 carrying wool or the like 17 through a backing, holding the loop 21 so formed in the fingers, pushing the needle through this loop to form a second loop 22, withdrawing the needle and pulling the loop 21 tight, Fig. 9. A series of these loops are made, the member 1 being pushed through before they are pulled tight, to ensure uniformity, Fig. 11. The former 1 is a U-shaped member with a sliding carrier 13 for a pivoted member 5 which has a razor blade 4. When the loops are formed, the carrier 13 is slid along the member 1 to cause the blade 4 to cut the loops. The pointed needle 14 is hollow to accommodate the wool and is threaded by the tool 23. Specification 436,104, [Group IX], is referred to.”

The present invention is an improved form of rug-making needle of this type. 20 According to this invention a rug-making needle of the type referred to has the point end of the hollow shank chamferred and backwardly bent in a smooth curve at the extremity of the chamfer, the 25 supply of wool, in the use of the needle, proceeding from the shank axially thereof. With this improved construction of needle the operations are considerably facilitated of threading the needle through one hole of the canvas backing under the strand thereof adjacent this hole and through the next hole above and subsequently through the loop which is then formed by holding between finger and thumb while withdrawing the needle through the said holes of the backing the length of wool which has thus been brought through the holes by the threading' therethrough of the needles, it being understood that the threading of the needle through the said loop is for the purpose of producing the loop which is afterward cut and at the same time for knotting the root of this loop to the said strand of the canvas backing.

The invention further comprises a two-part combination device consisting as regards one part of a rug-making needle of the above improved construction and as thereafter pulled tight over the bar (the knot which is formed at the root of the loop being for this purpose a slip knot), which thus serves also as a gauge to determine the size of the loop so that all of the loops eventually present on the bar in readiness to be cut by the running of a knife along the groove of the bar, will be of the same length and in consequence the depth of the pile will be uniform all along the line of cut loops.

The invention further comprises a three part combination device consisting of the above elements of the said two part combination and, for use in conjunction with these elements in the operation of cutting the load of loops on the knife guide, a knife element consisting of a safety razor or like blade mounted in a handle adapted to slide along the top of the knife guide with the blade in the groove thereof, the said handle being of greater width along the edge which is adjacent the knife guide in the sliding of the knife element therealong than the groove in the guide so that the top of the guide at either side of the groove constitutes a supporting rail for the knife element as the latter is slid along the guide to cut the loops. The knife element of this construction may for example consist of two thin cheeks of wood sandwiching between them a sheet metal holder for a safety razor blade, the holder being adapted to hold the blade in an inclined position relatively to the edge aforesaid of the handle and with the cutting edge projecting from said edge of the handle a. distance less than the depth of the groove in the knife guide so as to be traversable along 100 the groove clear of the bottom thereof. If desired the holder may also project from said edge of the handle in rear of the projecting portion of the blade so as to assist with the blade in guiding knife element along the grooved bar.

So far, this means a guide rod to keep consistent pile depth and a cutter so scissors weren’t needed. I have the punch needle and two rods/cutters, but the drawing shows parts 23, 24 and 25, which I don’t have (it’s a piece of wire with hooked ends). It would appear the loops are knotted at the base, like the short-pile method or Surrey Stitch, rather than just punched through. Parts 23, 24 and 25 are described:

The tool element shown in Figure 5 is for two purposes; firstly, for assisting in the operation of threading an end of the wool through a hole of the backing otherwise than by means of the needle, for example when starting- a row of loops at the edge of the backing, when it is usually necessary to form the first loop and its knot to the strand of the backing by hand; secondly, for initially threading the wool through the shank of the needle. For these purposes, the said tool element consists of a length of stiff wire 23 bent at the ends to the form of narrow hooks 24, 25 which are inserted respectively: the hooks 24 into the hole of the canvas backing to pick up the end of the wool to be drawn through the said hole by a reverse movement or withdrawal of the needle loaded with the wool through the hole, and the hook 25 into and through the shank of the needle to pick up the end of the wool to be drawn therethrough by a return movement in the same way of the loaded hook through the shank.